What is Powder Coating? How it Works & When Can Use

Usually, paints are solvents that evaporate, however powder coating has also been quite popular in the market recently.

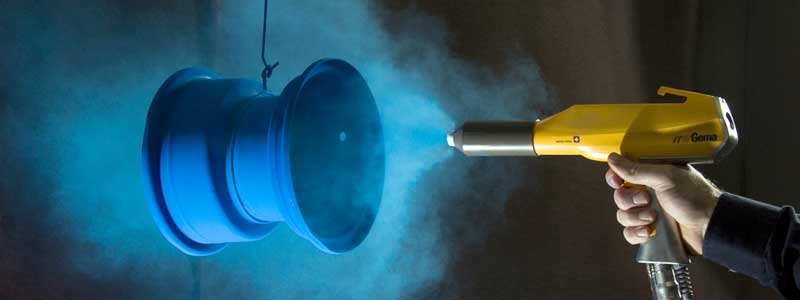

The electrostatic application of paint is called powder coating. The powder is dry and flows freely, and it can be thermoset polymer or thermoplastic.

It’s used when you desire a finish that is tougher than the regularly used paints. The process has been developed, so one process could cover a wider range of objects.

What is the powder coating?

The powder coating starts as a powder with very fine particles, which are made out of polymer resin.

This powder is applied to the surface, and then undergoes a chemical treatment for a finishing film to be created. There is a certain process for it to happen.

The process of powder coating

1. Preparation

Before applying the powder coating, the surface needs to be cleaned very thoroughly first. This is the most critical step when it comes to applying any coating.

This is because it is the cleanliness of the surface that determines the level of adhesion of the coat with the surface. If it is not done properly, issues will occur.

Most of the times, if you face any trouble in terms of coating, chances are that it occurred due to improper preparation, rather than the quality of the coat or the application process.

If you desire maximum adhesion between the two, the surface and the coating, you ought to remove the contaminants from your surface as best as you possibly can. This will ensure the best results.

The cleaning process is to be followed by etching, then rinse, and then, in the end, the cleaning process that is specific to the material that is to be painted.

2. Attachment

This step depends upon the kind of application.

If the surface is quite large, then the powder coating material is to be sprayed on to the surface, which has already been through the process of preparation.

However, if the object is relatively small, it can be dipped inside a fluid that contains the particles of the powder suspended in it.

Whatever the case may be, after the powder has reached the surface of the object, it has to be treated by either heat or electricity by the finishers.

3. The curing

The powder particles are separated from each other. They need to be melted if they have to spread out in the form of an evenly shaped film.

After the object undergoes the attachment process, it is placed inside a big oven, which makes sure that the powder on the surface melts.

The particles then merge to become a film. This film is quite thin yet quite strong.

Benefits of powder coating

As we can see, the method of application is unique if you compare it with the other painting techniques. Its uniqueness gives it many benefits that the other applications don’t have to offer.

Here are some of them:

· Increased durability<

The powder coating ensures more durability than traditional paints. It exhibits a surprising amount of strength against corrosion and abrasion, especially when you compare them to the liquid coats.

Moreover, the companies tend to add materials to the powder that enhance their corrosion-free properties. Which makes its use even better.

· Longevity

The best part about the powder coating is that it lasts for quite a long period, as it does not scratch or wear out.

You will notice that whatever around you has powder coating on it is going to last you longer than any other kind of paint. The colors of powder coating also remain vivid and bright.

It doesn’t matter how much you use your object. The coat’s quality is going to maintain itself for a satisfactory period.

· Variety

Powder coating is the only kind of coating that comes in numerous different finishes and colors, and what you choose depends upon where it is to be applied.

With powder coating, you can get a low and high gloss, metallic, and clear finishes. Color matching, however, might pose a challenge in this regard.

Color matching is more difficult in powder coating than it is in the liquid coating, but this issue does not arise if the painter is professional.

· Toxicity

The liquid coats are based on solvents, and they work on the principle of evaporation. The compounds that evaporate into the environment are toxic, for the most part.

This causes air pollution. The people who work in the area where such coats are being electrically or heat-treated can be exposed to harm if they are not protected properly.

The areas where liquid paint treatments have to take place also require much money to be spent on the exhaust systems and also the air treatments.

Powder coatings are proven to release the tiniest amounts of toxins, that are negligible. Moreover, the spray that is released into the air, 98% of it can be collected and reused on another surface.

And if you are using the dip-the-object-into-the-powder technique, then there is no way your power is going to go anywhere.

This means that when you are working with powder coats, there are little or no chances of being in a toxic environment.

· Cost-efficiency

There are so many benefits of powder coating. You do not have to be too skilled to do that, and the cleaning up process is also easy.

They last so many years, so you do not have to worry about them wearing out and repainting.

Where is the powder coating used?

The largest portion of the powder coating is consumed by the appliance industry. They constitute about 1/3 parts of the entire powder coating produced and used.

This portion uses powder coating due to many reasons, but the main one can be considered due to its resistance towards corrosion.

Apart from that, this kind of coating also looks aesthetic pleasing.

Here are the most common appliances that you encounter almost every day.

Read Also: How Oil Slows Down Rusting of Iron

· Microwaves, ranges, and refrigerators

Most of the paints become damaged if they are exposed to extreme hot or cold conditions. And the appliances mentioned above work under such conditions only.

Powder coatings are tough enough to deal with both the temperature extremes. And they don’t even flinch in the process.

This is the main reason why these appliances make use of nothing but the powder coating.

· Vending machines

It doesn’t matter if the vending machine is cooled or not. The fact that it is there for public use is enough for it to undergo enough harshness.

Vending machines are supposed to take much stress from the environment. They also need to maintain their looks in the process of attracting customers.

To protect the exterior of the machines, the creators use a powder coating.

· Dryers and washers

The washers and dryers have to go through a lot of wear and tear. Powder coating is now used instead of porcelain in them.

Because dryers and washers have to perform vigorous activities, they are supposed to be built out of extremely sturdy material.

Read Also: How to Unlock a Car with a Coat Hanger

Outdoor products

When you place something outdoors, you expect them to be used roughly, and their exterior is bound to wear out.

These products are built in such a way that they last while they are in use. But their paint jobs aren’t. In these cases, powder coating is the best option.

· Fam equipment

Such equipment is to be used daily, so they need to give a coat that doesn’t flake.

· Sports equipment

Outdoor sports are not just a test of the expertise of the player; it is also a test for the endurance of the equipment. Powder coating ensures they can withstand any conditions.

· Furniture

Anything you see in playground or lawns, like benches, use the powder coating. They do not give in to the sunlight or rain.

· Road signs

The signs must never be worn out; else, they will confuse. So they use a powder coating.

Construction and architecture

There is much scope of powder coating in the building and architectural market. That is mainly due to how durable they are.

Due to the variety, they have to offer, more and more construction companies are turning towards this idea now.

Stadiums

An innumerable amount of visitors are accommodated by visitors every day; stadium seats need protection from the sunlight as well as the people. So architects use powder coats.

· Doors and windows

The powder coats maintain the protective function, as well as the aesthetic function of the doors and windows.

· Poles and fencing

You can help prevent corrosion of the fences while maintaining their aesthetic appeal with this powder finish.

· Facades

The facades of structures need to be shielded from the unforgiving heat. So they turn to the powder coating.

Final Thoughts

In a nutshell, powder coating provides a sturdier finish than any other kind of coating.

And due to its wide range of appearances, it provides aesthetic appeal as well. Due to both of these reasons, it has many applications in the market now.

Share this content:

Post Comment